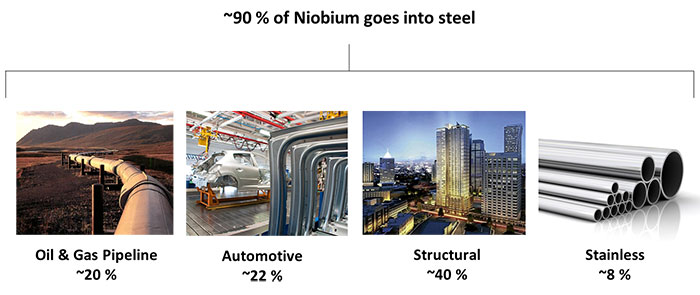

The Platinized anodes for Electroplating, Cathodic Protection, and Seawater Application

As our customer baseline is so diverse we place a high attention on staying in touch with evolution in key industries and registering our experiences. Ti Anode Fabricators Private Ltd, Madambakkam, Chennai, is the expert in the manufacture of Platinized niobium cantilever anode, Platinized Titanium anode for ships, Platinized Titanium Mesh anode, Rotogravure anode, and so on.

Ti Anode Fabricators Private Ltd proudly serve the aerospace, automotive, appliance, defense, corrosion protection, electronic, electrochemical, industrial, medical, and oil & gas industries, Chemical, Paper, Petrochemical & fertilizer application, Instrumentation engineering application. We also offer a wide range of metal alloy configuration accessible with practically proportion or thickness possible. The products can take the form of wire, rod, bars, ribbon, and plates.

Tiaano’s Platinized Niobium Anodes:

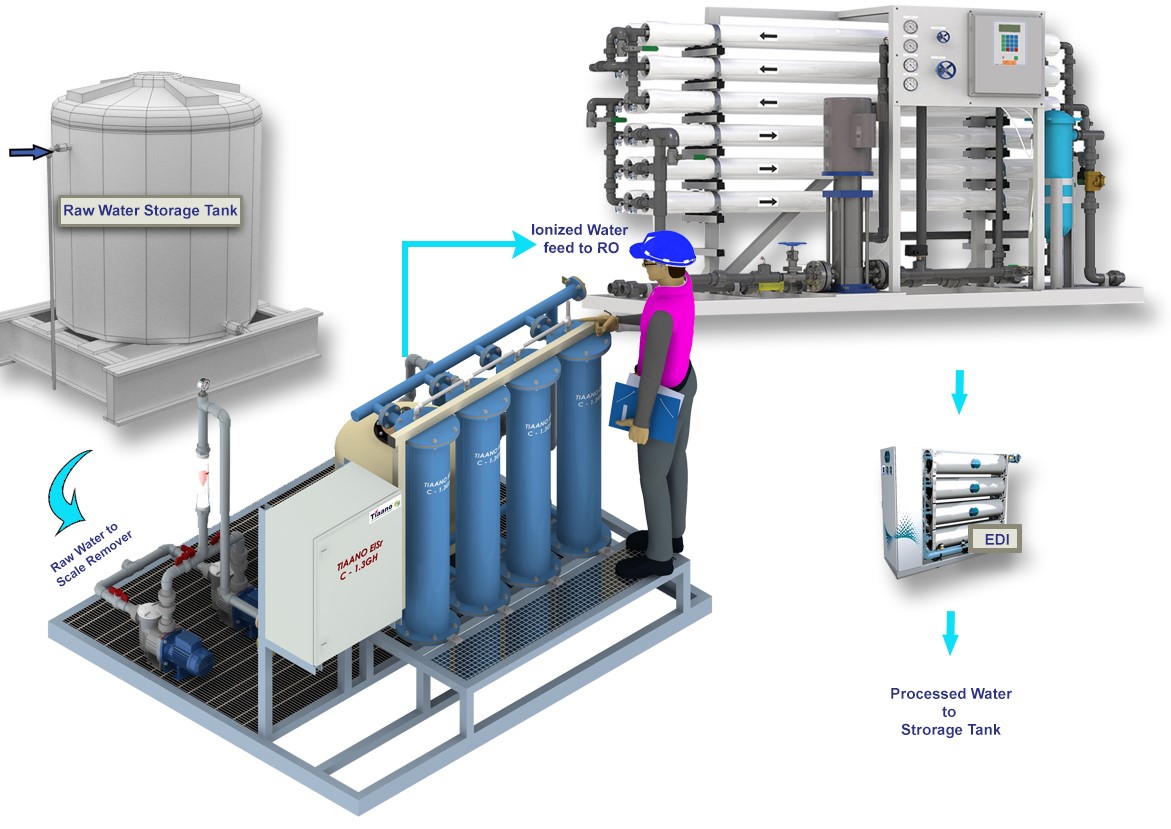

We design anodes for usage in all types of aquatic storage and process equipments. It is applicable for Electroplating, Cathodic Protection, Electro Dialysis, Electro Winning Process, Electrolytic Production of Sodium Hypo Chlorite, Seawater Application,Electrolytic Regeneration of Chromic acid, Electroplating for precious and base metals, Electro Synthesis of Organic & Inorganic Chemicals and Water Treatment.

.jpg)

.jpg)

.jpg)

The Niobium substrate is

- Resistant to corrosion,

- The anode remains dimensionally stable over its operating life

- Consumption of the platinum costing is extremely low.

Because of its low consumption rate, the anode may be employed in a protection system to achieve a design life of 6 years and above.

Platinized Niobium Anode is highly conductive and can be operated at a maximum current density of 100 amps/ft2. The anode is also Very light weight, flexible and strong. Tiaano’s Platinized Niobium Anodes are designed for use in all types of aquatic storage and process equipment. The anode has proven to operate effectively in fresh, brackish and salt water and is not adversely affected by Chloride concentration.

Tiaano’s Platinized Titanium anode:

Tiaano’s has delivered platinized Titanium and Niobium cantilever anode for ships. Platinized titanium is used extensively in cathodic protection particularly for sea water intake cooling towers structures and heat exchangers where its resistance to destruction is superior to any other anode coatings.

The Titanium substrate is:

- It possess High levels of adhesion of the precious metal coating

- It has improved resistance to acid attack

- Also has resistance to interface degradation by deposits

- It has significantly longer life

Tiaano’s platinum anodes are more specific with respect to application and it is also customizable. Platinized titanium manufactured by a special process in which the titanium substrate is modified prior to plating process. As a result of this process interface degradation and premature loss is undermining.

The manufacturing process includes application by thermal decomposition of noble metals followed by electroplating to produce a dense wear-resistant layer of platinum. A variety of shapes and forms are available including bar, rod, sheet and mesh. Individually fabricated anodes are available to suit customers’ special requirements.

Tiaano’s Anode for Hard Chrome Plating:

The Platinized Titanium and Platinized niobium either platinum electrodeposited or metallurgical clad anodes are used as insoluble anodes in hard chromium plating bath, electrolyte such as… Chromic - Sulphuric acid and HEEF-25 (high speed, etch-free). Due to its excellent characters of… Dimensionally stable, Flexible in custom-made, Easy electrolyte flow, High electric throwing power, Low weight, most of our anodes are made from expanded metal substrate.

Tiaano supports;

- Easy maintenance and handling.

- Low electric resistance.

- Energy saving potential.

- Dimensionally stable and insoluble character.

- Excellent high life with high current density.

- Possibility of re-use by re-plating of platinum.

- Usage in fluoride containing baths.

- · Excellent corrosion resistance characteristics.

.png)

.png)

.png)

.png)

Click here for our corporate profile.

·