Platinized Titanium and Niobium Anodes for metal finishing from Tiaano, the Innovative expert

Ti Anode Fabricators Pvt Ltd., (Tiaano®) India offers Platinized Titanium Anodes and Platinized Niobium Anodes for Electrochemical and Metal Finishing Industries.We perform the work with unique incorporation of expert Craftsmanship, finest Equipment and Space to ensure successful outputs. And also delivers world- class quality products that meet or exceed customer expectations.

Inert metals of...

Titanium, Tantalum, Niobium, Zirconium, Nickel & its alloys.

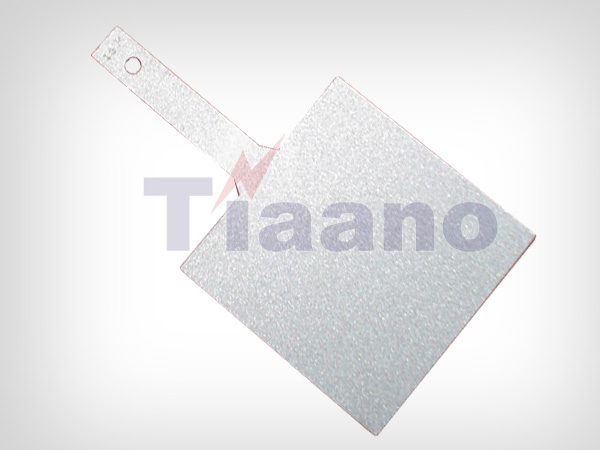

Platinum is one of the noble group of metals and also a precious metals. It replaced the conventional electrodes a few decades ago. The Pt anode’s sustainability, Geometrical stability and Calibration made the electroplating chemistry to be an ease and remarkable. It can be easily unplugged or relocated whenever required.

From Start to End:

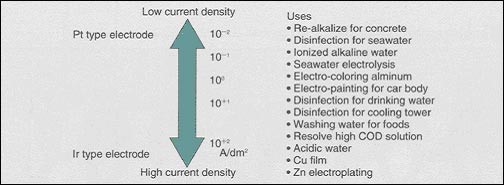

Due to its high- cost Platinum is made practical for use by electroplating a thin layer over an anti-corrosion substrate. Platinum anodes are produced by coating Platinum on a specially treated precious metal (Ti/Nb/Tt/Zr) by the process of electro deposition.

Titanium is less expensive however it has a breakdown at 12V hence the operating voltage is set to 8V in case of Marine applications. But for Cathodic protection, Niobium and Tantalum are preferred with operating voltage as100V. Sometimes Platinum anode gets affected by organic impurities like sugar or diesel and so rectification is introduced in midst of process.

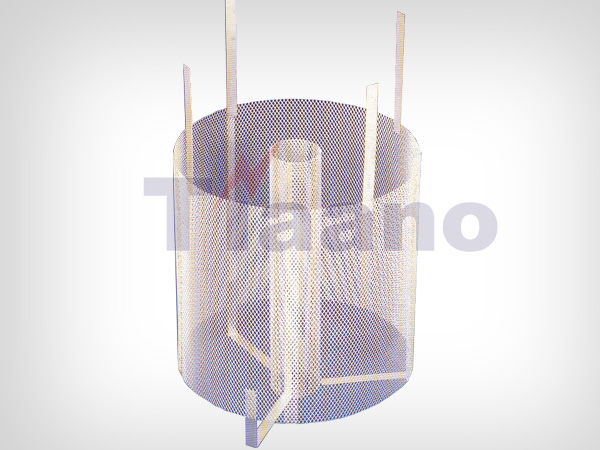

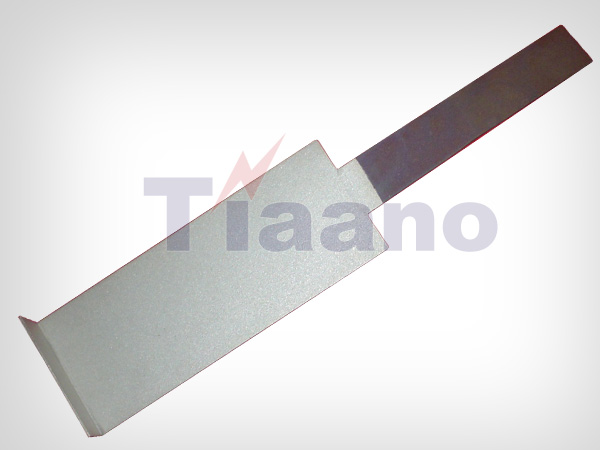

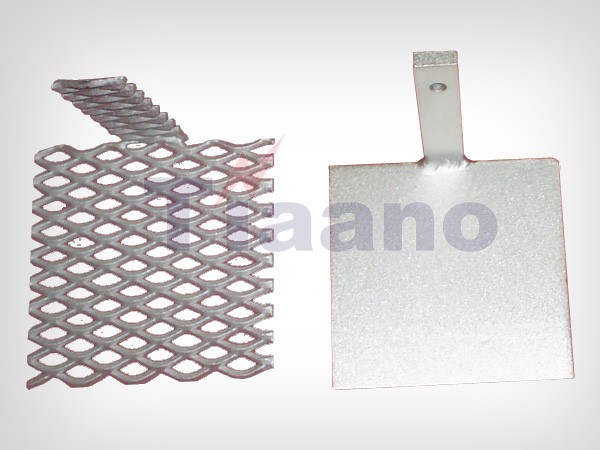

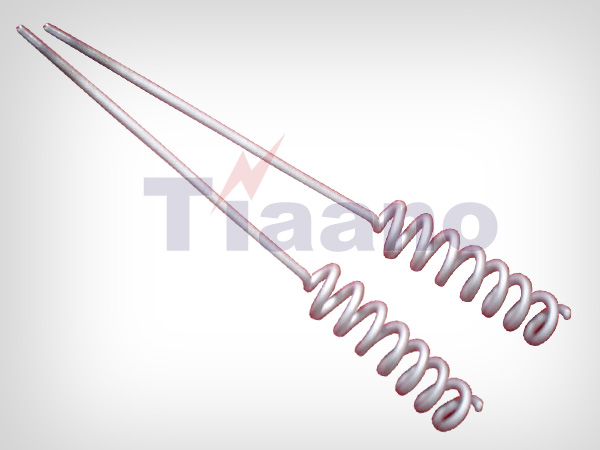

Tiaano fabricators have the technology to Platinum plate Titanium substrate in the form of wire, rod, tube, and mesh. Initially, the Titanium substrate exhibits corrosion before platting under the normal environment. So when Platinum has coated it becomes anti-corrosive. But the dimension of interface layer matters, since the Platinum has small pores and cracks which permits the direct contact of Titanium substrate with air thus leads to crevices and acidity formation. Thus the mechanical contacts between the inert metal (Ti) and precious metal (Pt) are decreased. The situation can be handled at mild condition except in the worst scenario.

Availability:

01. Platinized titanium anode 02. Platinized niobium anode

03. Platinized zirconium anodes 04. Platinized tantalum anode

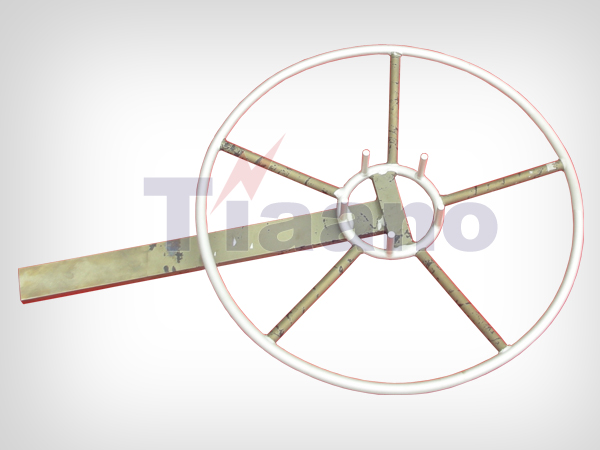

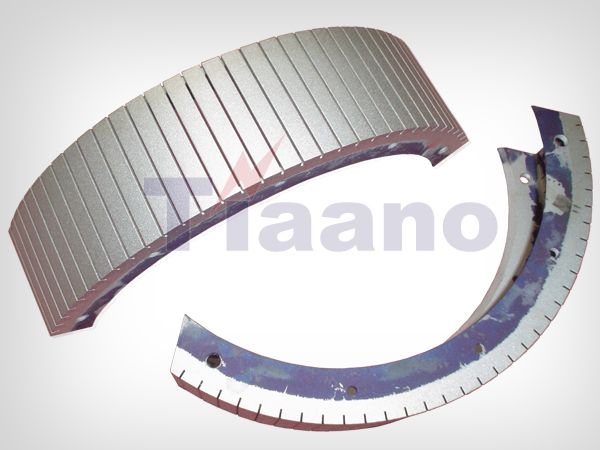

Platinized Titanium/ Niobium/ Tantalum Rod Anodes are widely used for internal protection of condensers, process equipment etc.

Platinized Titanium/ Niobium/ Tantalum Wire Anodes are used for internal protection of water tanks and pipelines.

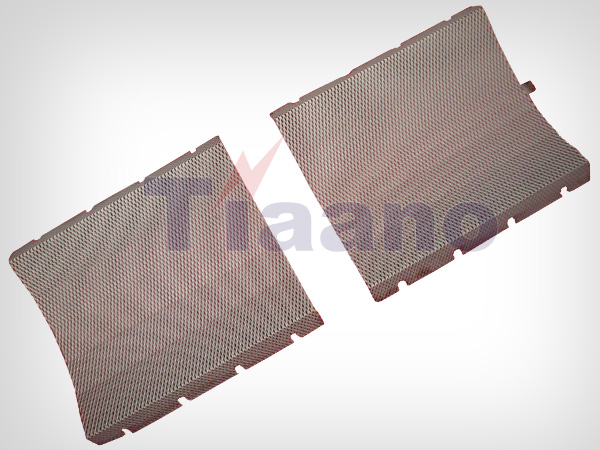

Platinized Titanium/ Niobium/ Tantalum Mesh Anodes are used for protection of reinforced concrete structures.

Merits:

· Manufacturing of complex shapes is possible

· Long lifetime

· Easy maintenance

· High dimensional stability and loading capacity

· Good corrosion resistance

· Low weight

· Perfect current and thermal distribution

· Consistent brightness throughout life

Our Work-loads:

o Hard chrome plating (piston rings, printing cylinders, etc.)

o Precious and non- precious metal electroplating

o Electronics and semiconductor industry

o Chemical process engineering

o Cathodic Protection

o Sodium Hypochlorite

o Electroplating

o Electro synthesis

o Electro dialysis

· Click here for our corporate profile