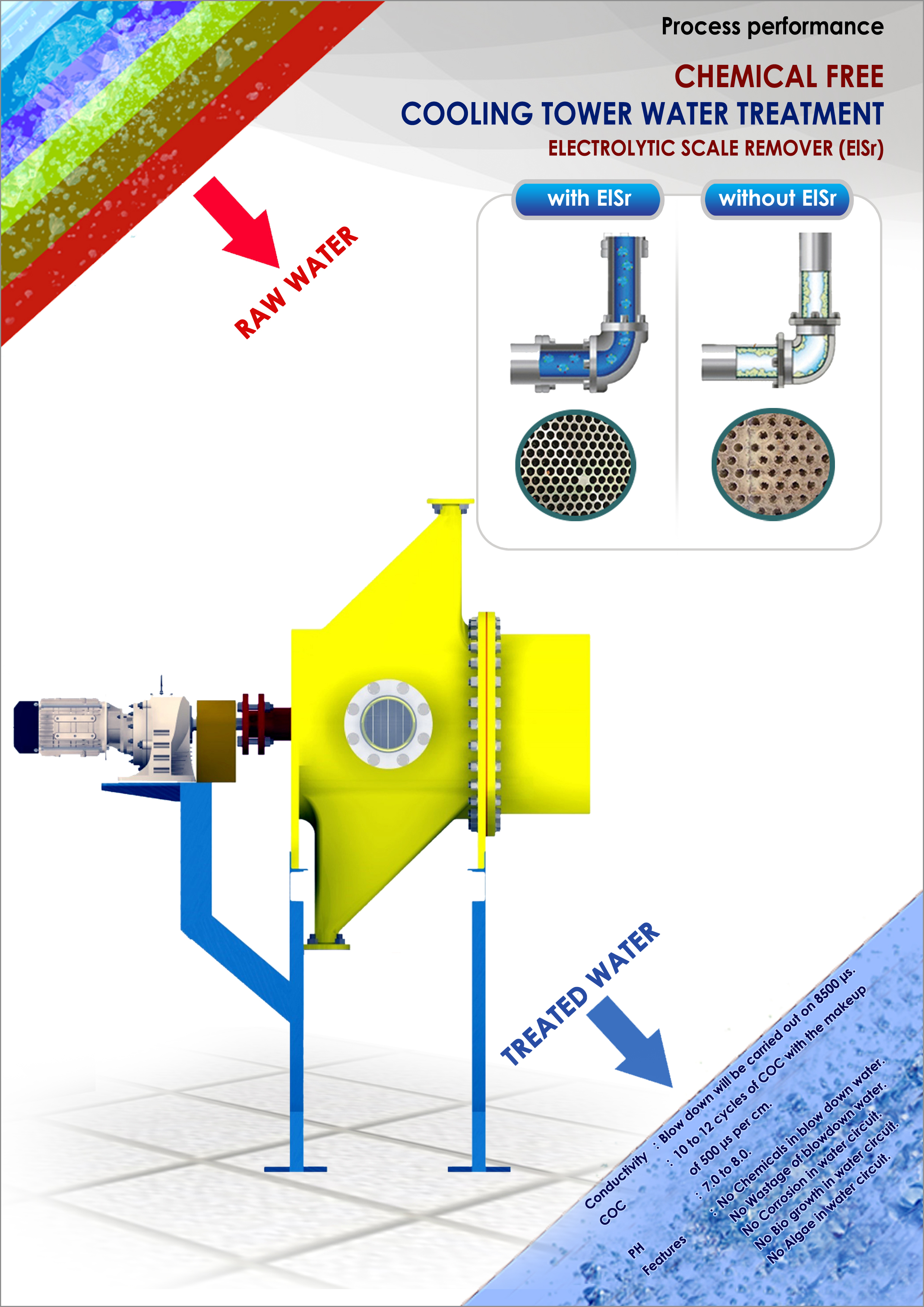

Scale Remover for Cooling Tower Water Treatment

Wherever there is a need for cooling tower, four factors cause concern for engineers & management. They are Scale, corrosion, Bio-fouling and algae. Together, they cause major problems including, health hazards, increased electricity bill, water consumption, and reduction in cooling efficiency and equipment life expectancy.

Scale:

Due to evaporation, concentration of salts in the cooling tower water increases constantly. This is the main reason for the deposition and scaling on cooling tower’s elements and inside the cooling tower pipes. Cooling tower’s scaling causes a diminution of the efficiency of the cooling tower efficiency.

Micro-organism & corrosion:

Cooling tower’s scaling is a natural habitat of legionella bacteria. Sunlight & water stagnancy is the cause for bio-fouling, micro-organism growth & spread of airborne bacteria.

Until now, the common method of treatment like chemical dozing or softening the water are getting adopted. The process in entailed the use of chemicals and unguaranteed results. Both inhibits scale deposition but have disadvantages:

Ø High operating and maintenance costs.

Ø Large quantities of cooling tower’s water bleeding.

Ø Soft water are very corrosive, damaging metal parts of cooling tower & its pipe.

Ø Both the process are eco-unfriendly.

In order to overcome the disadvantages of conventional cooling water treatment, Tiaano developed Electrolytic Scale Remover called “Electrolytic Scale Remover – ElSr’ – working based on electrolysis process. It removes scale and produces oxidant in the water in-situ, prevents – inhibits corrosion, bio-fouling, Micro-organism growth, Spread of airborne bacteria.

Ø Electrolytic Scale Remover (ElSr) eliminates chemical in water treatment.

Ø ElSr collect all free calcium carbonate and magnesium carbonate from the water and prevents any scale deposits on the cooling elements.

Ø ElSr fight with bio life and algae by the power of chlorine produced next to its anode.

Ø Process of electrolysis reduces water bleeding and total water consumption to two third of conventional consumption.

Ø It is ecologically safe and environmentally friendly.

Ø ElSr controlled by a microprocessor based PLC and its valve are electrically activated. Optionally it is available for manual operation.

Ø It extend the cooling tower life.