RELATION BETWEEN HEAT TRANSFER EFFICIENCY and POWER CONSERVATION WHILE USING ELSR UNIT

Electrolytic Scale Remover (ElSr) unit is nothing but an electro chemical reactor which perform against Bio fouling & Scaling without adding any external reagents. Tiaano conducted various field study on energy saving, while using Tiaano ElSr in Cooling Tower water treatment.

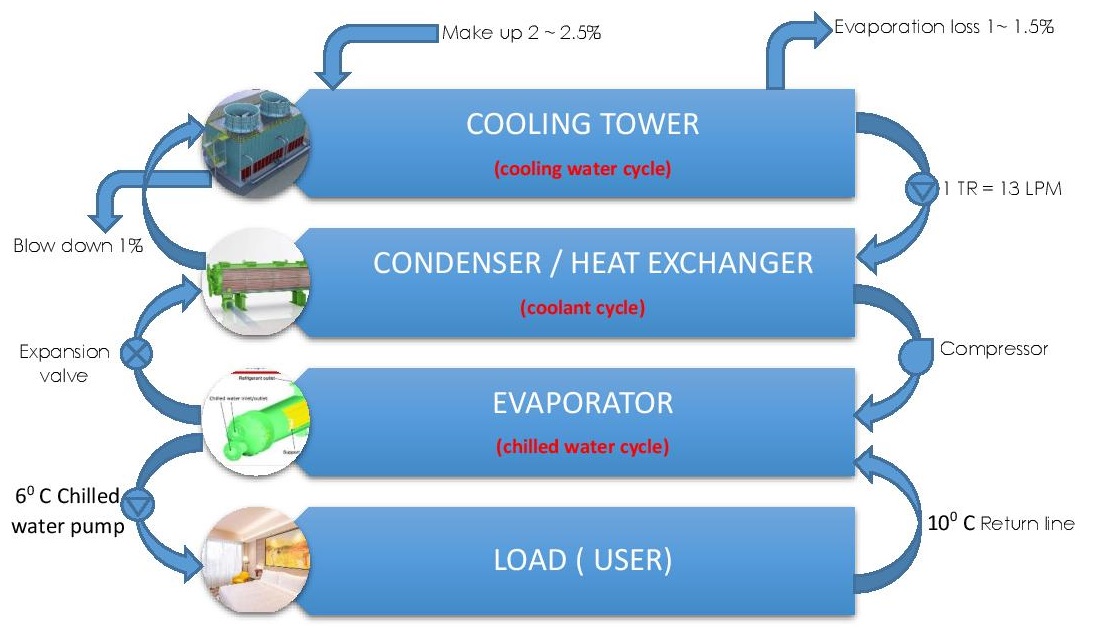

In general air conditioning / Cooling system contains three major loops as…

Ø Cooling water cycle (cooling tower),

Ø Coolant cycle (Condenser / Heat exchanger) and

Ø Chilled water cycle (Evaporator with compressor).

During the condensation process soluble mineral are deposited as scale in the condenser tubes and microscopic plant matters tend to deposit as biological film in the condenser tubes, collectively scales and biological film are known as fouling which result low heat transfer and high power consumption.

The overall heat transfer coefficient is influenced by the thickness and thermal conductivity of the mediums through which heat is transferred. Larger the coefficient is easier the heat transfer from its source to the product being heated. In a heat exchanger, the relationship between the overall heat transfer coefficient (U) and the heat transfer rate (Q) can be demonstrated by the following equation:

Q = UA Δ T

Where

Q = heat transfer rate, W=J/s [btu/hr.]

A = heat transfer surface area, m2 [ft2]

U = overall heat transfer coefficient, W/ (m2°C) [Btu/(hr-ft2°F)]

ΔTLM = logarithmic mean temperature difference, °C [°F]

From this equation it can be seen that the ‘U’ value is directly proportional to ’Q’, the heat transfer rate. Assuming the heat transfer surface and temperature difference remain unchanged, the greater the ‘U’ value, the greater the heat transfer rate. In other words, this means that for a certain heat exchanger and product, a higher ‘U’ value could lead to shorter batch times and increased production / revenue.

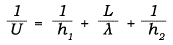

Calculation of ‘U’ value:

Several equations can be used to determine the U value, one of which is…

Overall Heat Transfer Coefficient

Where,

h = convective heat transfer coefficient, W / (m2°C) [Btu / (hr-ft2°F)]

L = thickness of the wall, m [ft.]

λ = thermal conductivity, W / (m°C) [Btu / (hr-ft°F)]

Heat transfer through a metal wall

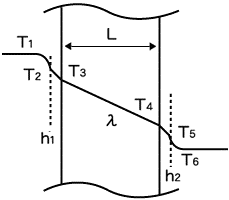

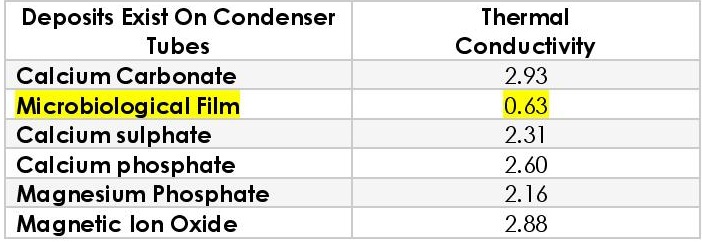

Overall Heat Transfer Coefficient reduces due to the formation of scaling and biological film as per following table, specifically microbiological film’s heat resistance is 5 times more than the scale.

Thermal conductivity:

Thermal conductive of each elements are differs with respect to its atomic structure but thermal conductivity of soluble minerals which are causing the scale / microbiological film formation are much lesser than the normal metals used in the general heat exchanger, comparison table as follows.,

Effect of Scale on Energy Consumption of Chillers:

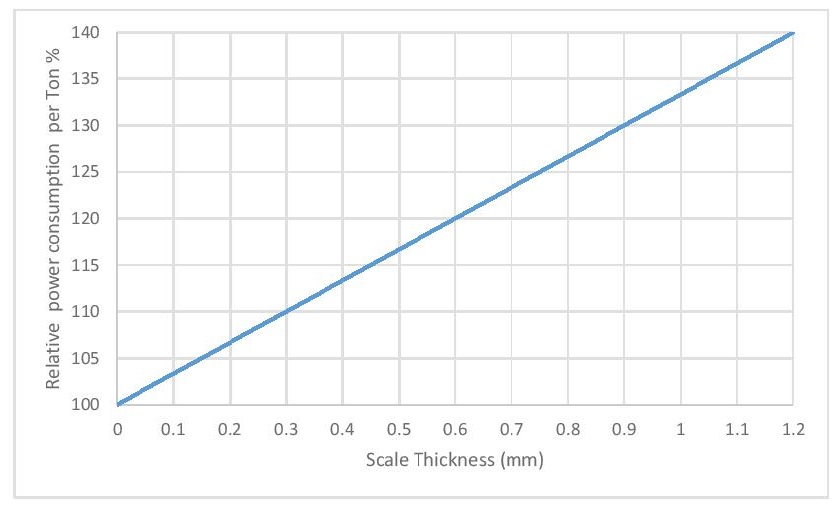

Chiller consumes more energy in order to compensate for scale fouling in the cooling tower water line as…

1. Compressor loaded extra to compensate the loss of heat transfer efficiency caused by scale formation.

2. Cumulatively 0.3 mm thickness of scale layer caused 10% of more energy consumption.

Conclusion

1. While adopting Tiaano ElSr unit above loss can be controlled as this unit will not allow the scale/fouling formation on condenser tubes.

2. ElSr treated / ionize the water through high frequency electric field which increase the thermal conductivity of water around 5%, resulting 3% of power saving.